> Quality Control

Process control

-

①DesignMost effective design to produce a best quality casting with lowest price.②ModelingAssemble wax/sand patterns into wax/sand custer "tree" to prepare an economic cast mold design.③MoldingA shell is formed with sodium silicate and ludox in a controlled drying room, lost wax inside the mode after it completely dried and solid, then washing and backing the empty shell before pouring.

①DesignMost effective design to produce a best quality casting with lowest price.②ModelingAssemble wax/sand patterns into wax/sand custer "tree" to prepare an economic cast mold design.③MoldingA shell is formed with sodium silicate and ludox in a controlled drying room, lost wax inside the mode after it completely dried and solid, then washing and backing the empty shell before pouring. -

④MeltingFast melting, by using the spectrometer to ensure an accurate chemical composition.⑤PouringControl the pouring temperature, speed and time strictly to ensure the best quality effectively.⑥FinshingShell knockout, cutting and surface treatment to achieve a smooth and clean appearance before shipment.

④MeltingFast melting, by using the spectrometer to ensure an accurate chemical composition.⑤PouringControl the pouring temperature, speed and time strictly to ensure the best quality effectively.⑥FinshingShell knockout, cutting and surface treatment to achieve a smooth and clean appearance before shipment. -

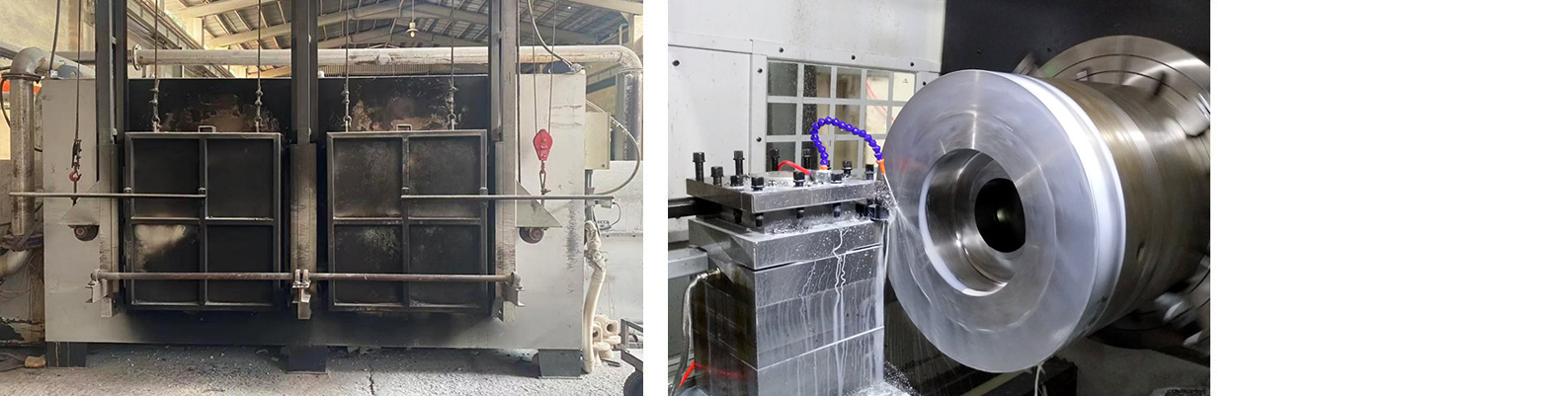

⑦Heat treatmentDifferent material using different heat treatment process to assure a strong mechanical property, then sand blast and acid passivation after the casting products cooling down.⑧MachiningStrictly control each part's accuracy by most precise machining according to customer's requirements.⑨InspectionInspection in accordance with requirements of customer and the related international standards.

⑦Heat treatmentDifferent material using different heat treatment process to assure a strong mechanical property, then sand blast and acid passivation after the casting products cooling down.⑧MachiningStrictly control each part's accuracy by most precise machining according to customer's requirements.⑨InspectionInspection in accordance with requirements of customer and the related international standards.

System control

-

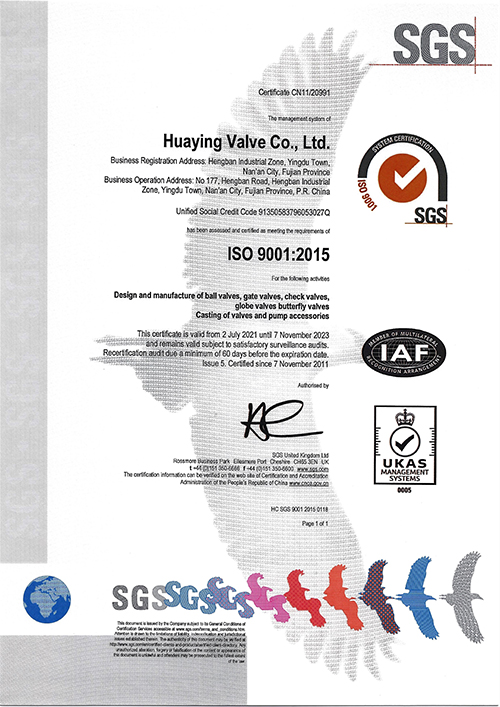

Quality management system certification certificate

Quality management system certification certificate -

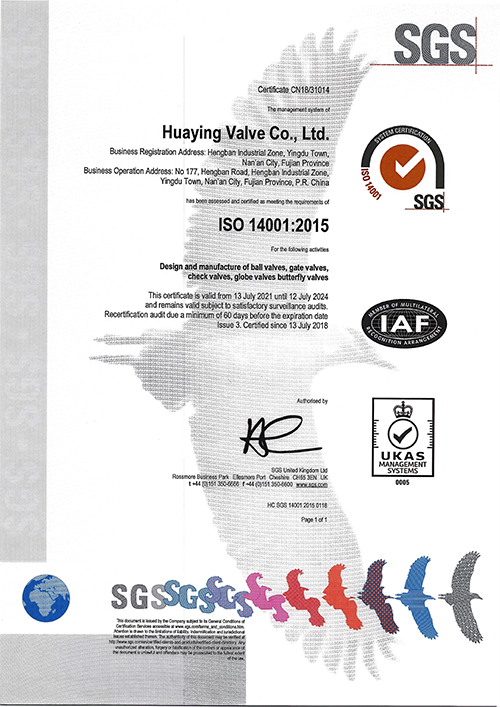

Environmental management system certification certificate

Environmental management system certification certificate -

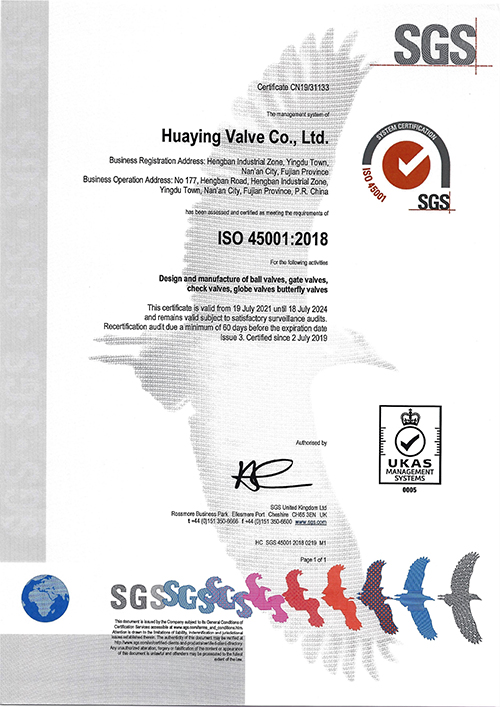

Certificate of occupational health and safety management system certification

Certificate of occupational health and safety management system certification -

CE certification certificate

CE certification certificate -

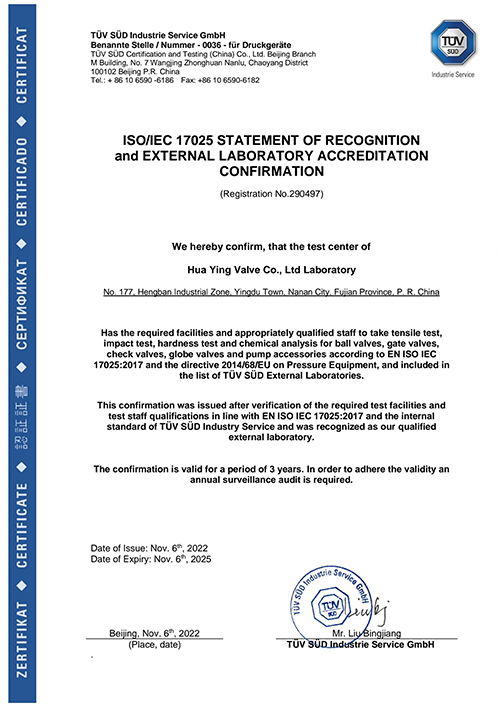

Laboratory certification certificate

Laboratory certification certificate -

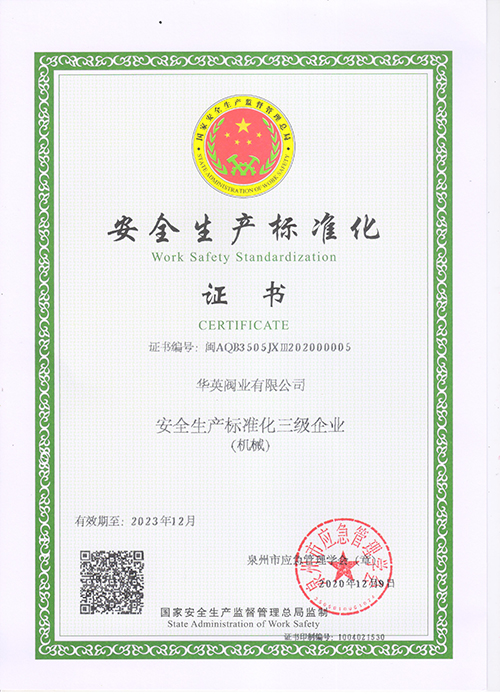

Safety production standardization certification certificate

Safety production standardization certification certificate -

High-tech Enterprise Certificate

High-tech Enterprise Certificate

Outcome control

- Metallographic analysis

- Size test

- Impact test

- Wall thickness test

- MT

- UT

- PT

- Stretch test

- Packing inspection